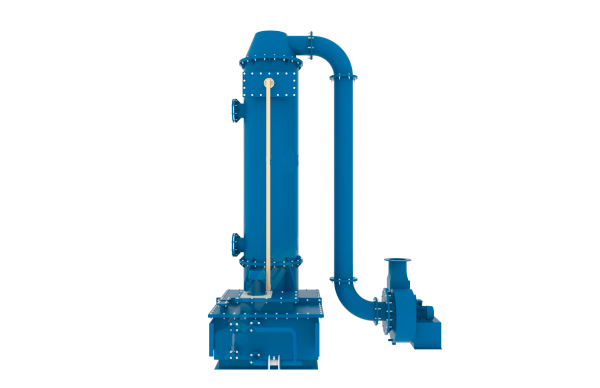

H2SO4(Sulfuric Acid) Scrubber

Many chemical industries generates and exhausts Sulphur based substances such as Sulfuric acids or Sulphur dioxide from various processes. Sulfuric acid fumes are very corrosive and it is strongly irritant to the respiratory if is directly inhaled. Experienced in controlling and neutralizing the sulphuric acid fume using a packed bed column with caustic recirculation.

Description

H2SO4 Scrubber works on principle of absorption technology. A column in which gas is passed at bottom and liquid is sprayed at opposite direction. Packing material is filled to bring the intimate contact between gas and liquid. There are two things happening here, providing cooling for exhaust gas and removing H2SO4 gas from exhaust.Apzem provides complete packages from start to end including water level controller using automated solenoid valve, pH controller with dosing system